-

Co-creative development

-

Precision at scale

-

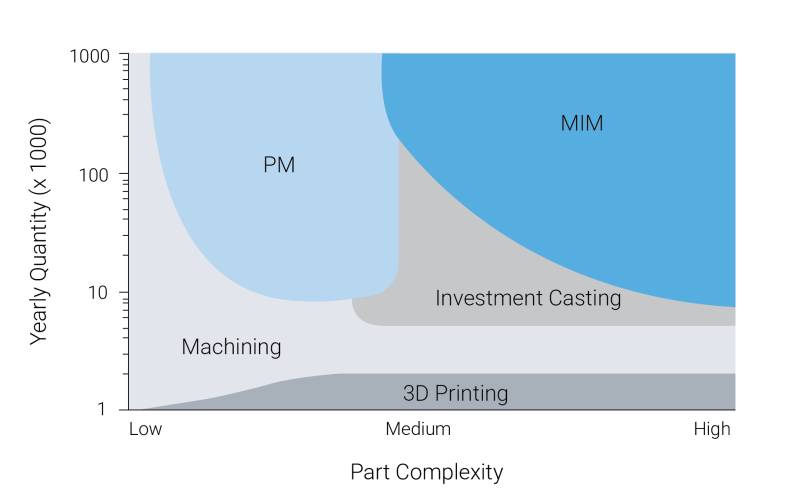

European Production

Often times, excellent and complex design solutions tends to fail commercially – but why? Usually the component is finished with labor-intensive technologies to ensure the right profile and structural design, or maybe it is 3D-printed to avoid the post-finishing. This results in high costs of production and the inability to quickly ramp up large volumes. This is where the technology of Metal Injection Molding (MIM) comes into play as shown in the graph below.

Sintex distinguishes itself as one of the few companies in Northern Europe employing Metal Injection Molding (MIM), a cutting-edge technique revolutionizing component manufacturing. With the majority of our supply chain operations located within Europe, we ensure efficiency and quality at every step.

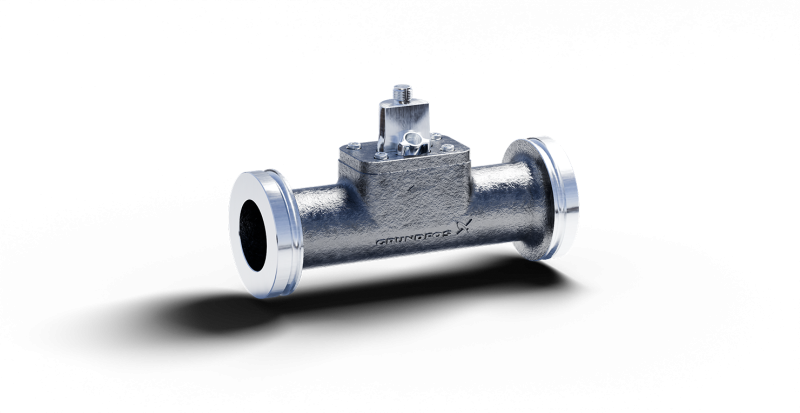

MIM technology enables us to produce large quantities of components with exceptional intricacy. Our capabilities extend across various industries, including food processing, thanks to the complex geometries and food-grade surface materials of our products.

What sets us apart is our commitment to tailored solutions for each client. We reject the notion of “one size fits all” and instead offer personalized consultations led by our team of experts. By collaborating closely on component design, we optimize functionality and efficiency, delivering superior results for our clients.

Our customized components vary in detail and weight, accommodating a wide range of specifications. Whether it’s small components at a few grams or larger ones weighing between 30-150 grams, our advanced production facilities can handle it all while maintaining fine tolerances. Unlike our competitors, we excel in producing sizable components, meeting demand with virtually unlimited volume.

But our differentiation doesn’t stop there. Our components boast unrivaled corrosion resistance, thanks to our development of high-performance alloys. These alloys enhance durability against corrosion, ensuring longevity and reliability in even the harshest environments. At Sintex, our plant only entails stainless steels.

Furthermore, our components are net shape, eliminating the need for post-processing once they leave our production line, hence ensuring high scalability in the continuous furnaces. This streamlined approach not only saves time but also maintains the integrity of the final product.

Combined with our minimal CO2 footprint, these attributes have garnered high praise from our customers and fostered a loyal clientel base. At Sintex, we are committed to innovation, quality, and customer satisfaction, setting the standard for excellence in the industry.

Industry: Motors & Pumps

Industry: Motors & Pumps

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.