-

Co-creative development

-

Precision at scale

-

European Production

The 3-dimensional magnetic properties of SMC result in completely new possibilities compared to traditional laminated sheet metal, which only has good properties in 2 directions (and in transformer sheet metal only 1 direction).

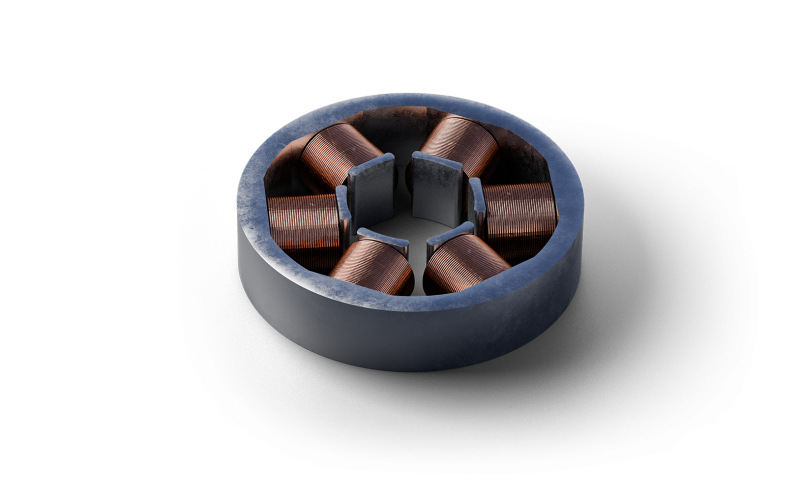

By exploiting these 3D properties, the component design can often be made smaller, lighter and more economic, and as such integration with the surrounding system also becomes easier as the number of geometric limitations is reduced. The complicated 3D geometry and alternative flux paths enable a high fill factor for both iron and copper windings.

Compared with laminated sheet metal, SMC components can be manufactured very efficiently in a single operation without a complicated manual handling process. The design of SMC is therefore not limited in the same way as laminated sheet metal, and the powder process is a well-established and highly suitable process for mass production. The result is efficient manufacturing of components at low cost, which means that the price of the end product can be on par with other solutions

B-H curve: SMC materials are isotropic 3D core materials with a maximum relative permeability in the range 100-700, which means that the material is 100-700 times better at conducting magnetic flux than air. Generally speaking, this figure is lower than for laminated sheet metal, but in practice this is of minor significance since the major part of the magnetic potential drop lies across the air gap.

Resistivity: The isotropic 3D resistivity lies in the range 20-10,000μΩm, which is considerably higher than laminated sheet metal, which is around 0.2μΩm. SMC components therefore do not need to be laminated to minimize eddy current loss.

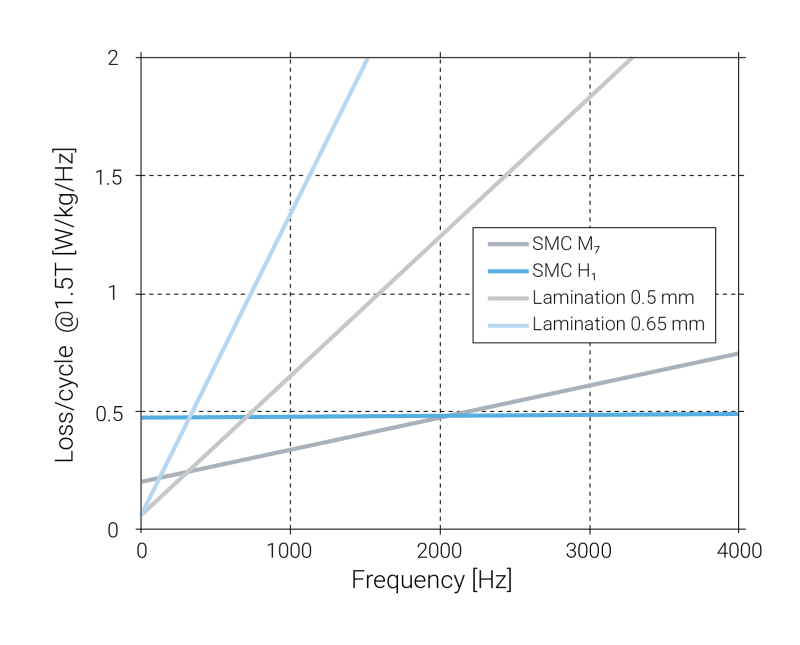

Iron loss: Iron loss occurs as a result of the material’s resistance to being magnetized (hysteresis loss) and as a result of electrical currents which counteract changes in the magnetic field in the material (eddy current loss).

The graph below shows the iron loss as a function of frequency for 2 selected material types and laminated sheet metal.

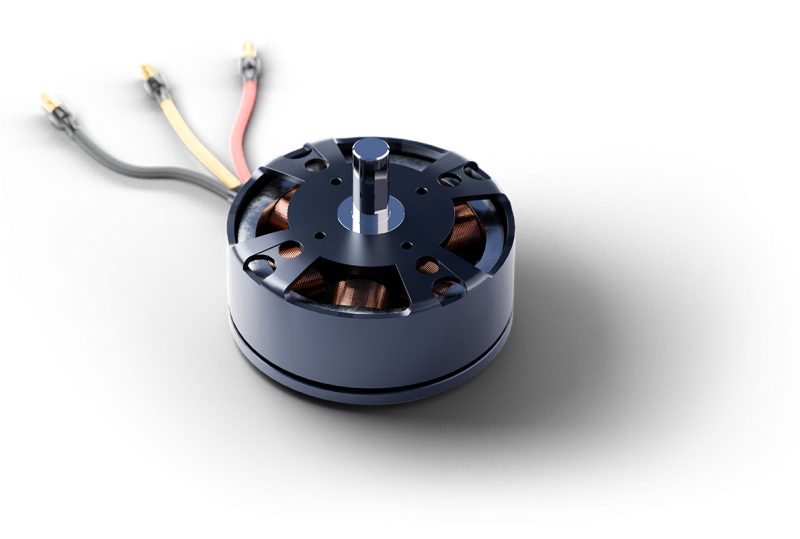

When designing electrical motors one of the limiting factors is the copper fill factor in the stator. It can be very easy to design and simulate the motor with a high filling factor, but on the other hand it can be extremely difficult to place the copper in the slots and also have space for the needle between the stator teeth and the stator bridges.

At Sintex we have developed a new solution to ensure a high filling factor enabling us to manufacture motors with high very power density.

When developing future products it is important to ensure that the raw materials can be separated and recycled in order to reduce the impact on our environment as well as to build up an urban mining system with a sustainable economy. One of the tools to decide for one solution over another is Life Cycle Analysis (LCA). It is known that separation of the laminated stator iron from the copper windings can be difficult or costly in man power. Therefore it is often seen that the entire motor is recycled as steel scrap resulting in copper pollution of the steel and the need to add virgin iron material to dilute the copper.

When designing a motor based on SMC separation of the copper from the stator can be done by a simple crushing machine ensuring a 100% recycling of the scarce copper material. Sintex has been collaborating with a local university on LCA and can help our customers with the optimized design towards a low LCA impact of their electrical motors.

Industry: Stator design with SMC

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.