We’re changing the world.

Magnetic Couplings

Options for Magnetic Couplings

Magnetic couplings

Sintex a/s is a specialist in the production of permanent magnetic couplings in corrosion-resistant materials. We have always focused on providing maintenance-free solutions with unique advantages – both compared to mechanical solutions and other magnetic solutions.

Our couplings are used within, for example, the pump industry, the pharmaceutical industry, the chemical industry, the biotechnical industry and the food industry – usually with application in:

- submersible pumps

- circulation pumps

- household pumps

- wastewater pumps

- industrial pumps

- liquid systems

- mixers and agitators

- hydraulic and process technology

How does it work?

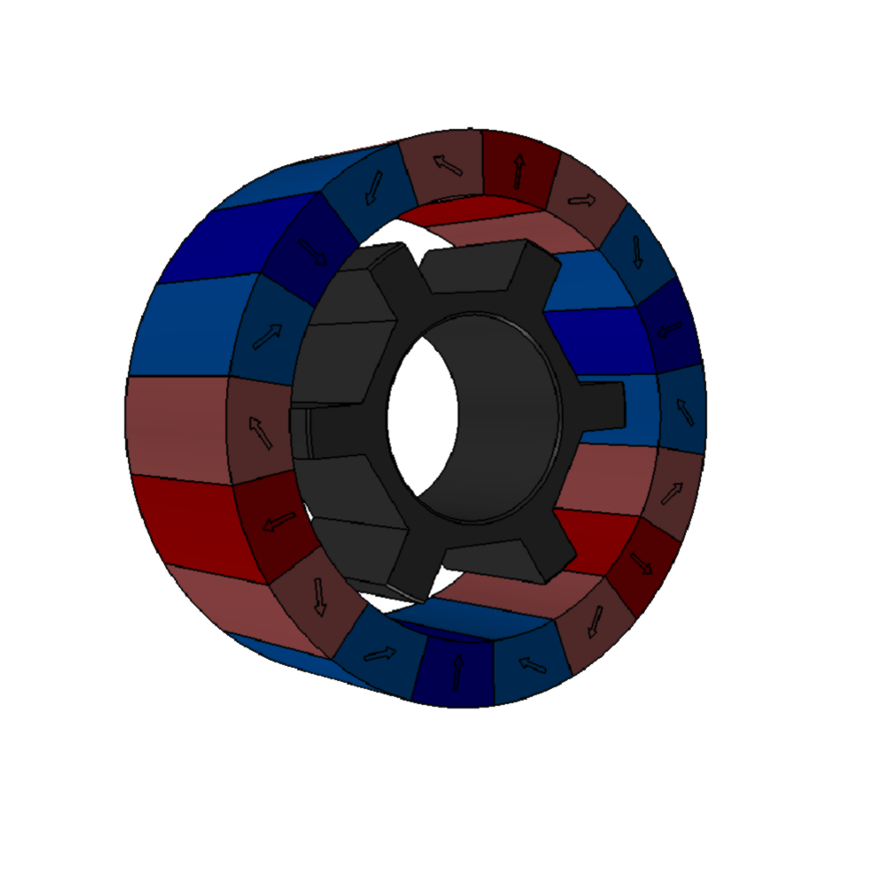

Magnetic couplings consist of an outer and an inner drive. There is no contact between the outer and inner drive, instead, the power is transmitted using magnetic forces. This means that the magnetic solution – in contrast to classical mechanical solutions – does not experience any wear.

See figure to the right: 3D model of magnetic coupling

The magnets can be fully enclosed in stainless steel to protect them against all external factors, and the coupling can operate directly as a wet runner in liquids, if wanted.

It is possible to place a separation can between the two rotating drives to isolate two different medias, for instance, to keep liquid on one side and air on the other side. Sintex provides a unique can with a thickness equal to just four sheets of paper, thus allowing for a high energy efficiency while maintaining high strength.

Uniqueness of magnetic couplings

Sintex magnetic couplings provide a wide range of advantages both compared to mechanical solutions as well as other magnetic solutions. Figure 2 summarizes the main advantages.

Permanent magnetic couplings have also been found to permit higher assembly tolerances compared to mechanical solutions.

See figure to the right: Advantages of magnetic couplings

Products

Sintex

Unlike traditional solutions, magnetic couplings can accommodate considerable differences in eccentricity between the shafts. This results in greater flexibility in the radial and axial alignment of the system, and the load reduction on the bearing system.

Innovation

Sintex’ innovation department provides consultancy services in connection with product development. We are very interested in open cooperation to optimize the product, material know-how, processes and production, thus enabling our customers to lead the way within new technologies and manufacturing processes in their core business areas.