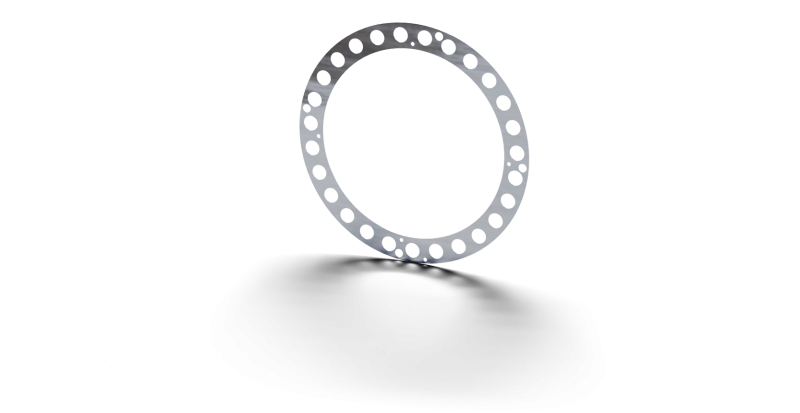

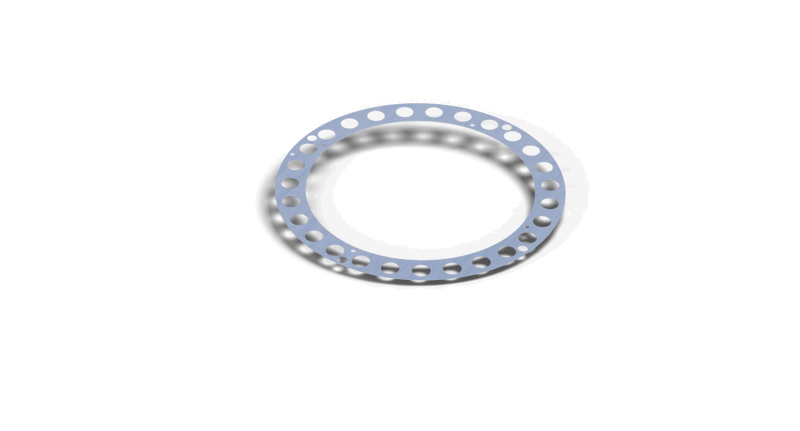

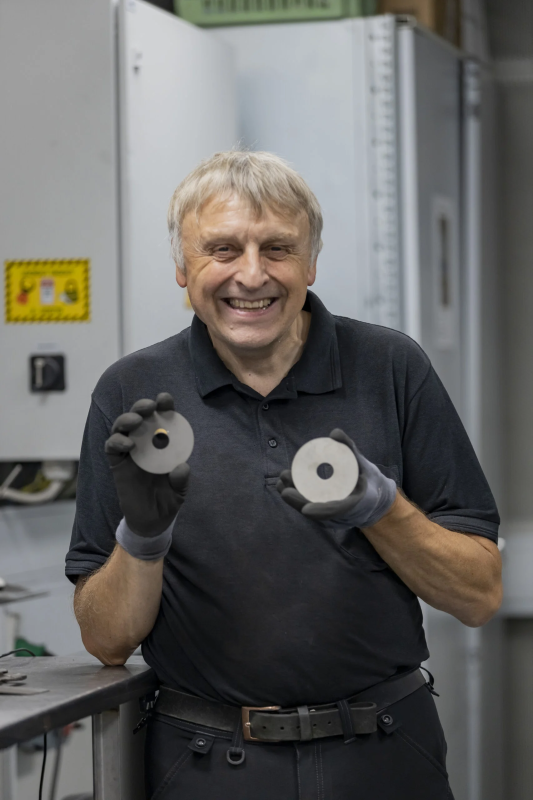

Friction Shims

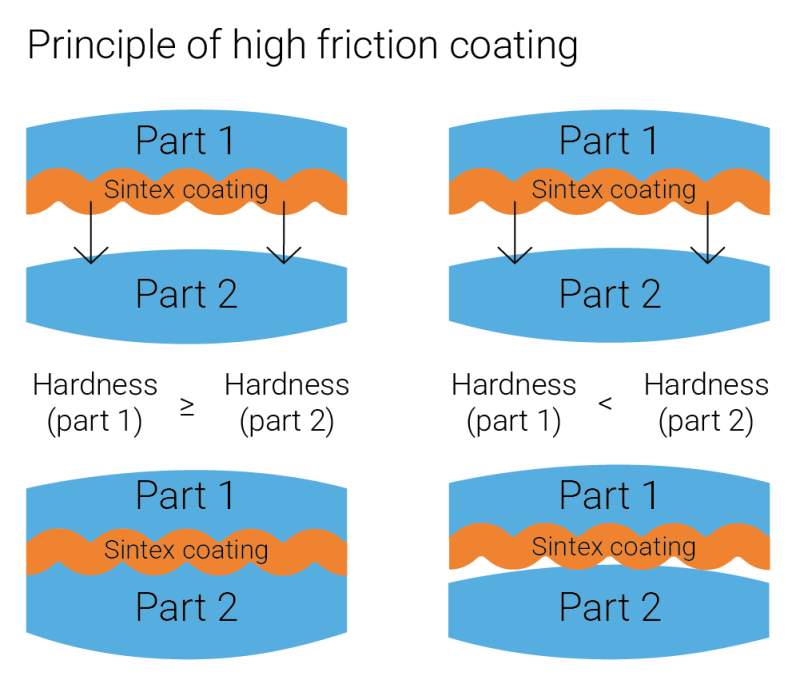

Large mechanical constructions are often assembled with many bolts that are tightened with very high forces in order

to avoid slippage. This can cause breakdown due to the fatigue of the tightened bolts and can increase repair costs and downtime.