-

Co-creative development

-

Precision at scale

-

European Production

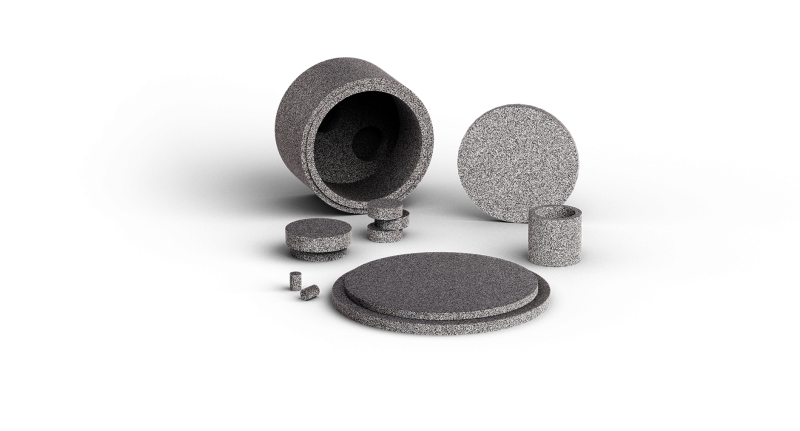

The variation of pore size and carefully controlled pore distribution are utilised to produce filters that feature a wide range of different applications.

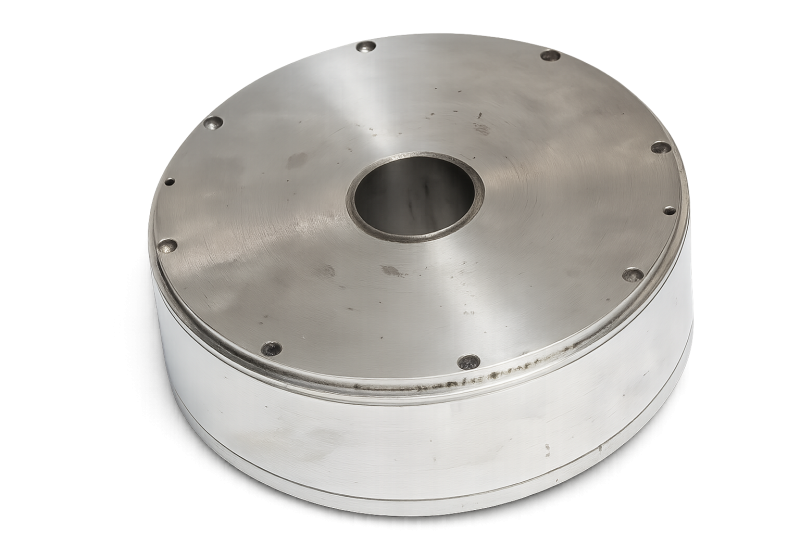

Sintered components’ special property in terms of porosity is utilised to produce filters that do not suffer from the same shortcomings as conventional solutions. The sintering process holds the material together so that stainless steel sintered filters are both stronger and better than conventional filters.

Sintered filters have fine tolerances and considerable geometrical possibilities. For instance, it is often possible to reduce the number of subcomponents and processes in the final filter solution, since a number of the subcomponents can be replaced by a single filter that is compressed in a single process. This avoids further time-consuming machining. The method chosen depends on the proposed application of the filter.

The wish to improve a filter in high-tech measuring equipment resulted in a successful cooperation between a customer and Sintex a/s. The starting point was two filters and a machined component which were assembled to form a flame trap. By employing Sintex’ innovative approach, the new solution was reduced to a single component manufactured in just a single production process. The sinter technology thereby reduced the costs of further processing and assembly of subcomponents.

Sintered filters can provide significant benefits within a number of sectors of industry. For example, we supply filters in a material certified for use with drinking water. Sintex® stainless steel sintered filters are used today in both the food and pump industries, in the chemical sector and for analytical purposes.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.