Stator design with SMC

Stator design is one of the interesting applications for SMC. With the right design, one could potentially make a cheaper, smaller and more efficient motor…When using SMC for a stator, it is important to utilize its unique geometrical possibilities in order to get the desired benefits. Replacing a stator in laminated steel with an identical one in SMC will rarely be beneficial, as the price is roughly the same, but the SMC will have a slightly higher degree of iron loss.

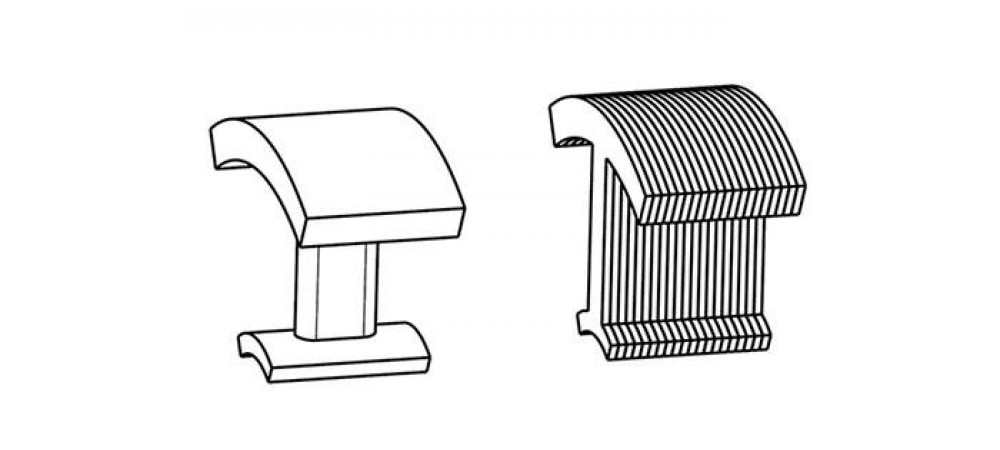

Instead, it is preferable to shape SMC in all three dimensions, which is not possible with laminates. In the following example, a comparison between a stator made in 0.5 mm laminated iron and STX B7X SMC is made. The stator design is similar except the tooth length has been shortened and rounded as can be seen on the above drawing.

Basic motor specification:

- Stator outer diameter: 80 mm

- Stator length: 20 mm

- Stator teeth: 6

- Rotor outer diameter: 28 mm

- Ferrit-Rotor

- Poles: 4

Loss

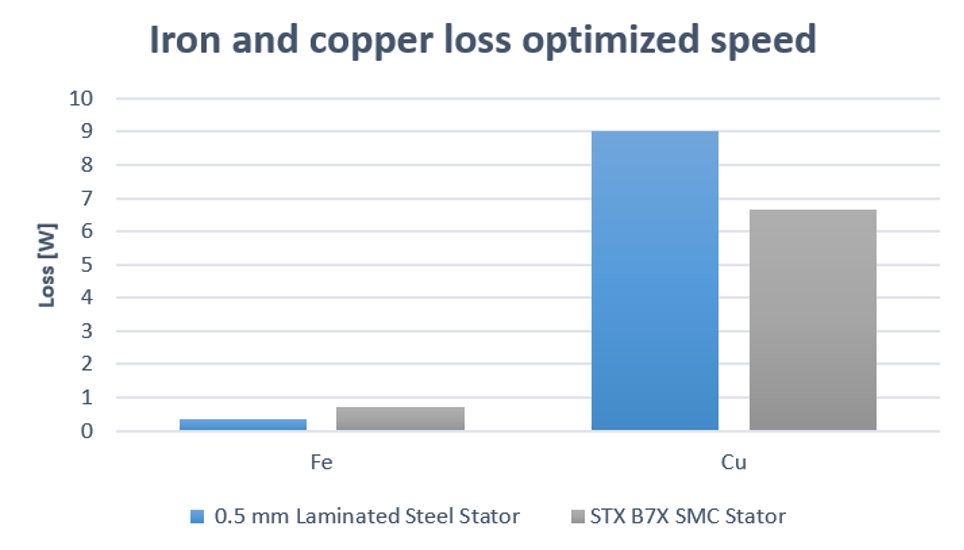

By utilizing the optimized shape, it is possible to use less copper while maintaining the same number of windings.

If we look at the diagram, it is evident that the iron loss will be higher for SMC compared to laminated iron, but the copper loss is significantly lower when using the optimized SMC shape. The outcome is a lower combined iron and copper loss resulting in a more efficient motor.

Copper cost

Decreasing the length of the copper winding also has a cost saving aspect.

The total copper weight of the stator:

- Laminated tin: 172.5 g

- SMC material: 115.8 g

In this case the copper weight is reduced by more than 30%, thereby lowering the material cost.

Size

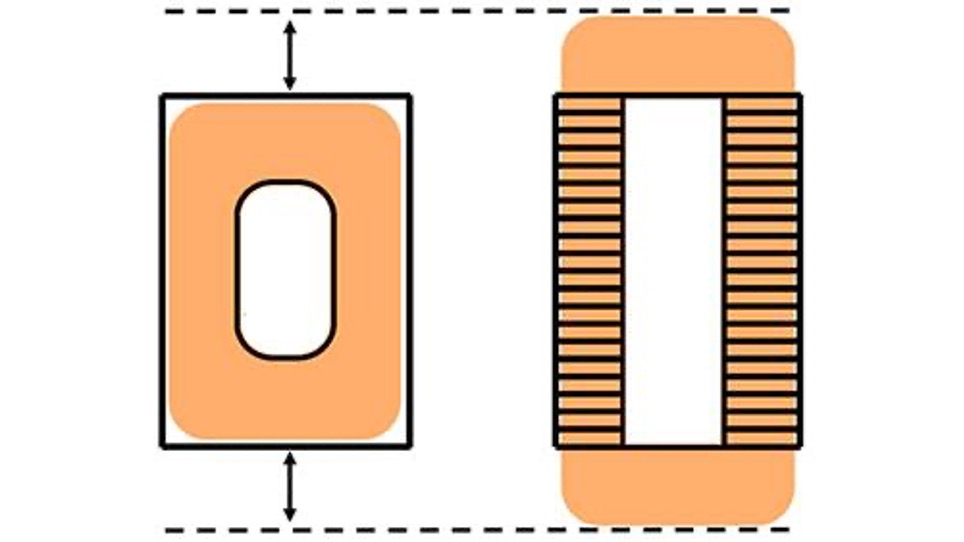

Due to the optimised shape, the end windings will protrude less beyond the stator with SMC (left) compared to laminated core (right) which makes it possible to decrease the volume of the entire motor.

All simulations have been done using SPEED PC-FEA.

- a cheaper solution

- a smaller motor

- a more efficient motor

… and not least a technological boost to your products, which can also have an impact on the bottom line!