-

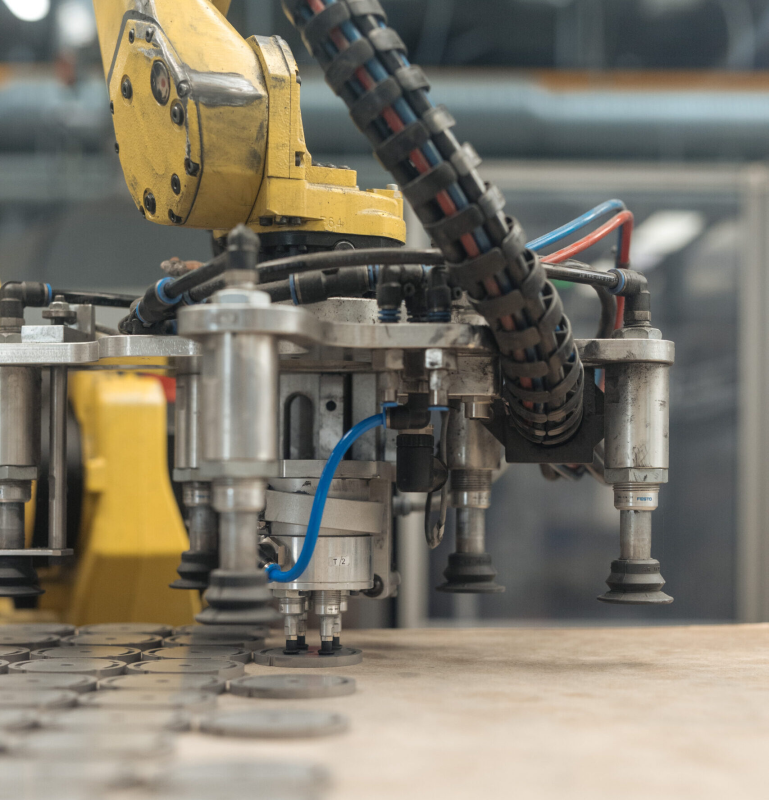

Co-creative development

-

Precision at scale

-

European Production

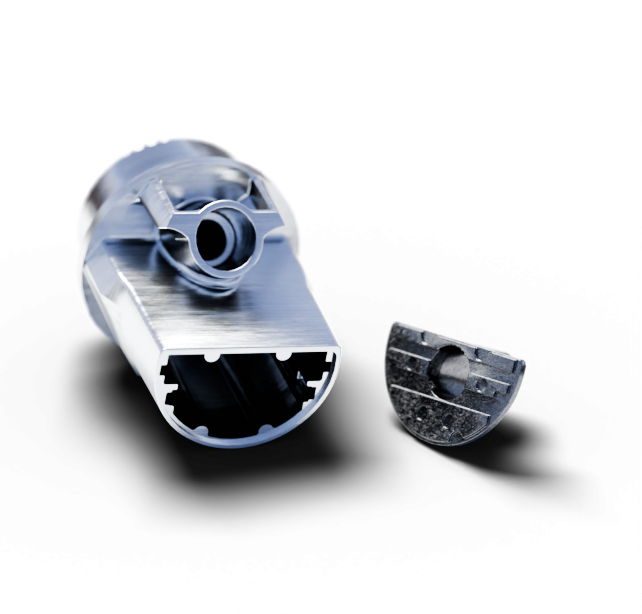

Complex geometries in stainless steel alloys can be produced in many ways, however, components often need to be post processed to reach the required tolerances for your application. This often increases material waste and production costs, and results in a poor LCA (Life Cycle Assessment) score as well.

To avoid this, powder metallurgical processes can be used in cases where material yield is typically above 97% to ensure a strong LCA.

However, the porosity of powder metal components compromises the corrosion resistance.

Like conventional materials, sintered components can be given finishing treatment, but the sintering technology often removes the need for time-consuming machining. Furthermore, the technology can reduce the number of subcomponents in the final solution by replacing multiple subcomponents with a single component and using a single production process. As a result, the components are technically homogeneous with better design, and the increased material and energy savings reduce impact on the environment.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.