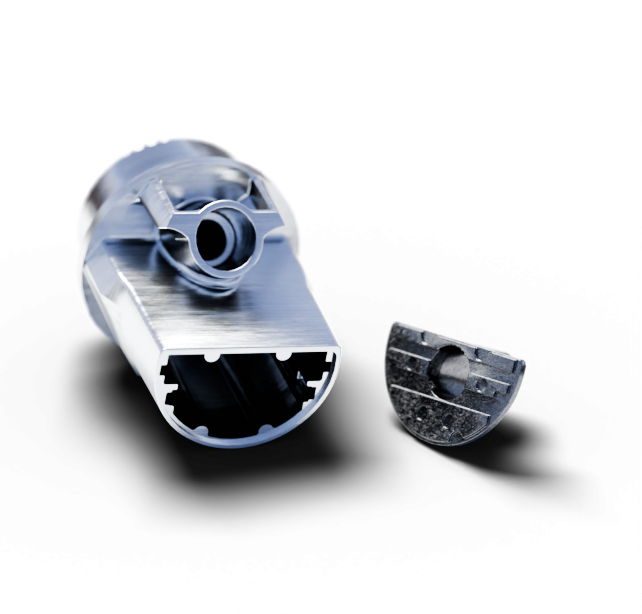

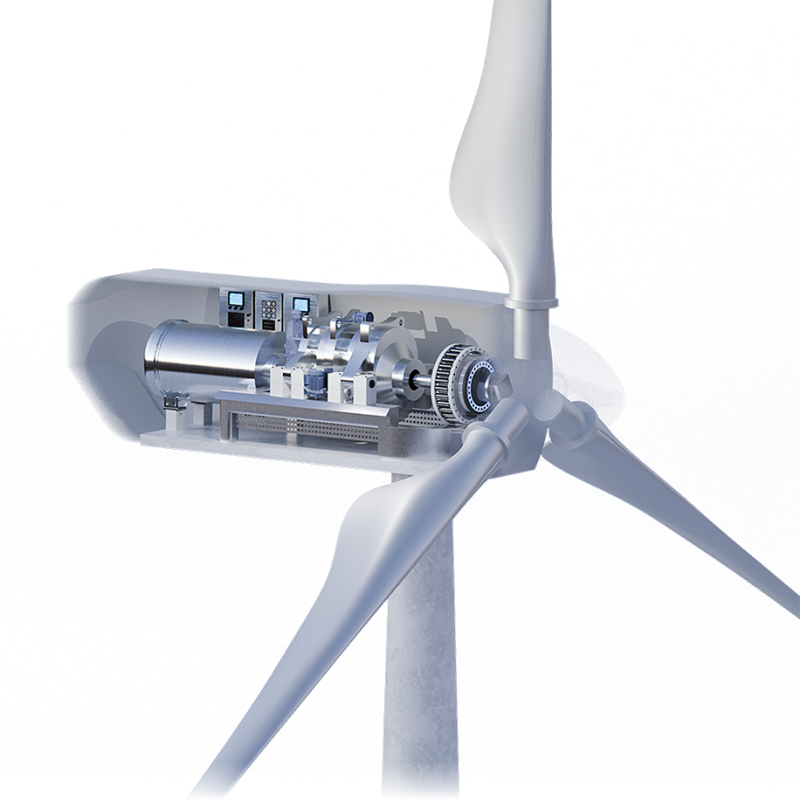

Metal Injection Molding

European Production using Metal Injection Molding, using a cutting-edge technology that enables large quantities of components with exceptional precision.

+

%

%

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.